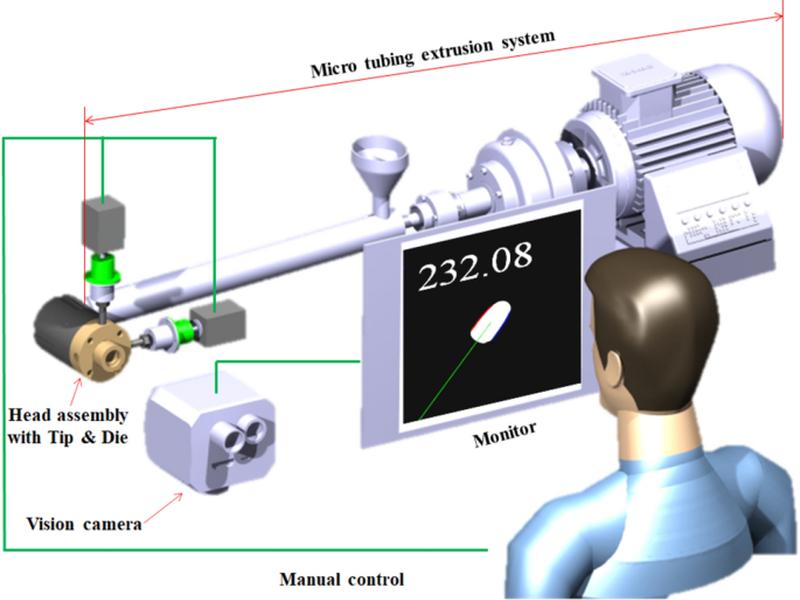

This article discusses a deep learning algorithm developed to quantify the extrusion angle of resin in the manufacturing process of medical tubes. The proposed method uses deep learning-based segmentation to segment the resin and outer line and quantifies the extrusion angle using the pixel coordinates of the outer line segments. The developed technique can be used to determine whether there is an abnormality in the process, as well as to be used as a judgement index for adjusting the relative position of the tip and die.