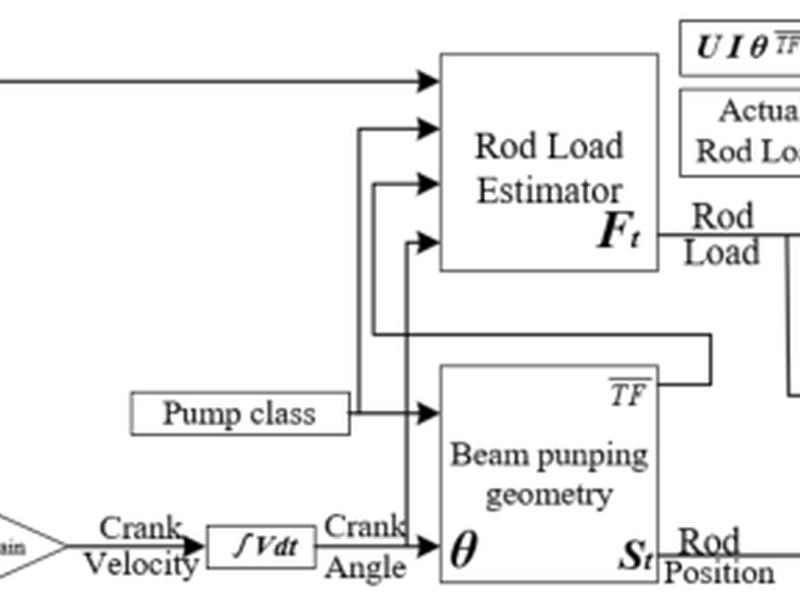

This article discusses a new mixed model for obtaining dynamometer data from pumping units in oil fields. The model uses motor electrical parameter data and a convolutional neural network to accurately estimate motor speed and torque output. This method is more reliable and accurate than traditional methods that use load sensors, which are prone to damage and errors in harsh oil field environments.