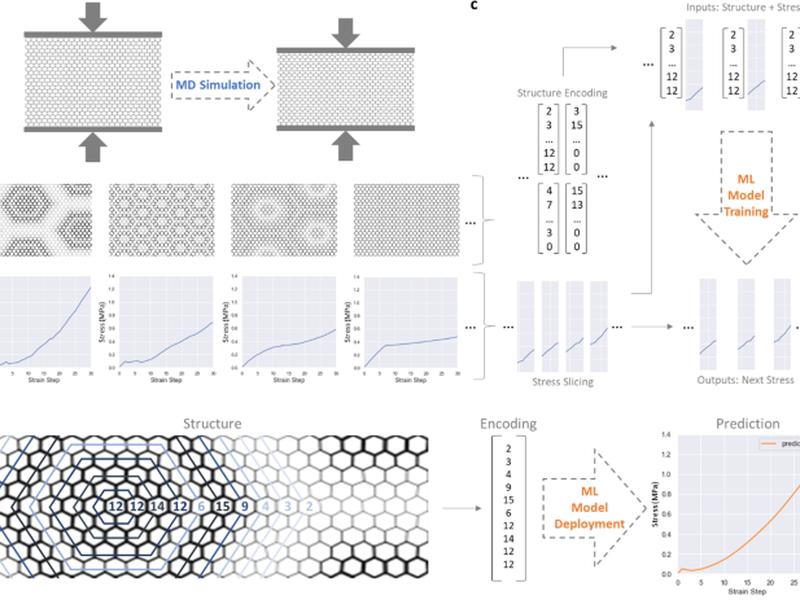

This article presents a workflow for the design of architected honeycomb materials, utilizing simulation to determine insights into the space of hierarchical honeycomb lattices, machine learning and genetic algorithms to generate candidates for desired behavior, and additive manufacturing to rapidly test top structural candidates. A coarse-grained molecular dynamics approach is used to simulate the compressive behavior of honeycomb structures, and a training set is developed to capture the behavioral space of physical behavior obtained by creating complex patterns of hierarchical honeycomb structures. The framework developed here could be directly applied by retraining or fine-tuning the machine learning model to fit the material behavior to a specific material.